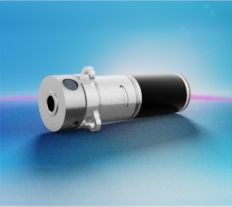

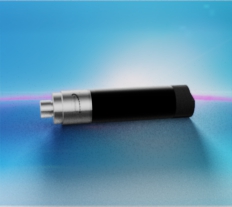

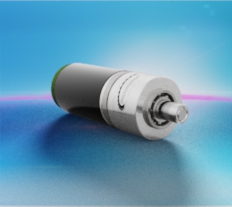

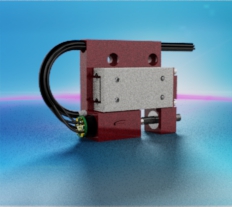

BryleeDrive® HighRes 26mm – Type 1

The BryleeDrive® HighRes 26mm – Type 1, a multi-axis micro system ideal to serve in optical applications.

The system has two degrees of freedom and offers therefore a joint virtual pivot point.

Precise mirror orientation about the theta-phi-axis with maximum repeatability can easily be realised and is conditonal i.e. for exact pointer applications.

Robust stepper motor technology enables both axes to be operated in an open loop control.

A high-stressable CoograDrive® gear with adjacent worm gear actuates the second axis which works with a zero-backlash MaalonDrive® gear and a reduction ratio of 500:1.

This setup saves space and, more importantly, weight and can easily be integrated in the application.

Benefits

1) Compact build up

2) Extreme low mass

3) Extreme power density

4) Wide travel range

5) 2 rotational degrees of freedom

Technical parameters

The values shown are based on calculations and measurement procedures carried out by Micromotion GmbH, which are carried out according to the current state of the art. Our definitions can be found at www.micromotion-drives.com. For further information please contact sales@micromotion.de.

Global system

Nr.

Parameter

Symbol

Value

Properties

P-004

x

P-004:With self-locking, the forces caused by friction are always greater than the applied adjustment forces due to the geometric relationships of the sliding partners. Due to the geometric conditions, the sliding partner in which the force is initiated cannot be moved relative to the sliding parter on which the adjustment force is applied.

Self-locking

ja

P-005

x

P-005:The travel range describes the travel range available for the application.

The travel range characteristic describes the characteristic of the travel range as a function of the angular position of the eccentric. It is defined such that at an angular position of 0 degrees, the eccentric is perpendicular to the resulting movement direction and has no deflection in the adjustment direction.

The max. travel range specifies the maximum available travel range of an eccentric kinematics.

Travel range

s

100° mm

P-034

x

P-034:The service life is defined by means of the rated operating point, i.e., rated speed and rated torque, as well as a change of the accuracy characteristics, i.e., unidirectional repeatability, transmission accuracy, lost motion, of less than 10% of the respective catalogue value.

Lifetime for rated operation

500 h

P-035

x

P-035:The backlash can be determined from the course of the hysteresis curve of a gear or mechanical transmission system. The backlash is defined as the range in which the course of the hysteresis curve is vertical, i.e. there is a change in angle or position without changing the torque or force. The hysteresis curve is determined by loading the output with a clockwise and counterclockwise torque or force when the drive is blocked and measuring the associated angular torsion.

Radial backlash output shaft

0 μm

P-036

x

P-036:The backlash can be determined from the course of the hysteresis curve of a gear or mechanical transmission system. The backlash is defined as the range in which the course of the hysteresis curve is vertical, i.e. there is a change in angle or position without changing the torque or force. The hysteresis curve is determined by loading the output with a clockwise and counterclockwise torque or force when the drive is blocked and measuring the associated angular torsion.

Axial backlash output shaft

0 μm

P-037

x

P-037:Stiffness of the bearing in the radial direction, i.e., elastic deflection of the mounted shaft in the radial direction as a function of the applied force.

Radial stiffness

c

1.1 N/μm

P-038

x

P-038:Stiffness of the bearing in the axial direction, i.e., elastic deflection of the mounted shaft in the axial direction as a function of the applied force.

Axial stiffness

c

9.1 N/μm

P-039

x

P-039:Max. permissible radial load on the output shaft (not in operation, force applied constantly)

Describes the maximum permissible radial load on the output shaft, whereby the drive is not in operation, i.e., is at a standstill and the force is applied statically. The static load-bearing capacity of the ball bearings Co and the geometric relationships from the point of force application and the bearing distance are decisive for the determination. For the permissible force, the worst case is assumed as the point of force application, i.e., the maximum distance between the ball bearings and the end of the output shaft.

Max. radial load on output shaft (non-operating, constant load)

F

25 N

P-040

x

P-040:Max. permissible radial load on the output shaft (not in operation, force applied impulsively)

Describes the maximum permissible radial load on the output shaft, whereby the drive is not in operation, i.e., is at a standstill and the force is applied impulsively. The load-bearing capacity of the ball bearings is decisive for the determination. With impulsive loading, the permissible load-bearing capacity of the bearings is reduced to one third of Co.

Max. radial load on output shaft (non-operating, impulsive load)

F

20 N

P-041

x

P-041:Max. permissible radial load on the output shaft (in operation, force applied constantly)

Describes the maximum permissible radial load on the output shaft, whereby the drive is in operation and the force is applied statically. Particularly important for the determination of the permissible force in the dynamic case are, in addition to the load-bearing capacity of the ball bearings, the stiffness of the bearing and the run-out error on the dynamic spline caused by elastic deformation. For the permissible force, the worst case is assumed as the point of force application, i.e., the maximum distance between the ball bearings and the end of the output shaft.

Max. radial load on output shaft (operating, constant load)

F

43 N

P-042

x

P-042:Max. permissible radial load on the output shaft (in operation, force applied impulsively)

Describes the maximum permissible radial load on the output shaft, whereby the drive is in operation, i.e., is turning, and the force is applied impulsively. With impulsive loading, the permissible dynamic load-bearing capacity of the ball bearings is reduced to one third of Cr. Likewise decisive for the determination are, in addition to the load-bearing capacity of the ball bearings, the elastic deformation of the output shaft near the dynamic spline and the associated run-out error due to the stiffness of the bearing.

Max. radial load on output shaft (operating, impulsive load)

F

43 N

P-043

x

P-043:Max. permissible axial load on the output shaft (not in operation, force applied constantly)

Describes the maximum permissible axial load on the output shaft, whereby the drive is not in operation, i.e., is at a standstill and the force is applied statically. Decisive for the determination is the static load bearing capacity of the ball bearings as well as the elastic deformation of the output shaft due to the stiffness of the output bearing and the associated position of the dynamic spline.

Max. axial load on output shaft (non-operating, constant

F

64 N

P-044

x

P-044:Max. permissible axial load on the output shaft (not in operation, force applied impulsively)

Describes the maximum permissible axial load on the output shaft, whereby the drive is not in operation, i.e., is at a standstill and the force is applied impulsively. Decisive for the determination is the static load bearing capacity of the ball bearings, which, in the impulsive case, corresponds to just one third of Co, as well as the elastic deformation of the output shaft due to the stiffness of the output bearing and the associated position of the dynamic spline.

Max. axial load on output shaft (non-operating, impulsive load)

F

20 N

P-045

x

P-045:Max. permissible axial load on the output shaft (in operation, force applied constantly)

Describes the maximum permissible axial load on the output shaft, whereby the drive is in operation, i.e., is turning, and the force is applied statically. Decisive for the determination is the dynamic load bearing capacity of the ball bearings as well as the elastic deformation of the output shaft due to the stiffness of the output bearing and the associated position of the dynamic spline.

Max. axial load on output shaft (operating, constant load)

F

74 N

P-046

x

P-046:Max. permissible axial load on the output shaft (in operation, force applied impulsively)

Describes the maximum permissible axial load on the output shaft, whereby the drive is in operation, i.e., is turning, and the force is applied impulsively. Decisive for the determination is the dynamic load bearing capacity of the ball bearings, which, in the impulsive case, corresponds to just one third of Cr, as well as the elastic deformation of the output shaft due to the stiffness of the output bearing and the associated change in position of the dynamic spline.

Max. axial load on output shaft (operating, impulsive load)

F

25 N

P-057

x

P-057:Minimum permissible temperature at which the drive may be stored or decommissioned without being impaired or destroyed as a result.

Min. permissible ambient temperature (non-operating)

T

-20 °C

P-058

x

P-058:Minimum permissible temperature at which the drive can be operated.

Min. permissible ambient temperature (operating)

T

0 °C

P-059

x

P-059:Maximum permissible temperature at which the drive may be stored or decommissioned without being impaired or destroyed as a result.

Max. permissible ambient temperature (non-operating)

T

80 °C

P-060

x

P-060:Maximum permissible temperature at which the drive can still be operated.

Max. permissible ambient temperature (operating)

T

60 °C

Material information

P-900

x

P-900:At Micromotion GmbH, hazardous materials, which are referred to in EU directive 2011/65/EU, are purchased/used only in compliance with this directive.

RoHS compliant

ja

Axis 1: rotational axis

Nr.

Parameter

Symbol

Value

Material information

P-003

x

P-003:The reduction ratio describes the relationship between the input movement and the output movement. With a reduction ratio, the output movement is smaller than the input movement.

Ratio

i

2400 : 1

P-008

x

P-008:The unidirectional repeatability describes the positional uncertainty that arises when repeatedly approaching a setpoint from the same direction with no load.

The repeatability is defined as half of the maximum difference together with a +/- sign.

Repeatability unidirectional

10.03 arcmin

P-009

x

P-009:The bidirectional repeatability describes the positional uncertainty that arises when repeatedly approaching a setpoint from the opposite direction with no load.

The repeatability is defined as half of the maximum difference together with a +/- sign.

Repeatability bidirectional

30.045 arcmin

P-010

x

P-010:The positioning accuracy of a gear describes the maximum deviation of the output angle relative to the setpoint or, with a linear actuator, the maximum deviation of the output position relative to the setpoint.

The measurement is performed during a complete rotation of the output element or a complete traverse of the travel range path with the aid of a high-resolution measurement system.

There is no change in the direction of rotation or direction reversal.

The positioning accuracy is defined as the absolute value of the maximum difference between the theoretical setpoint position and the measured actual position of the output element.

Accuracy

30.09 arcmin

P-011

x

P-011:The transmission accuracy of a gear describes the linearity error between input and output angle.

The measurement is performed during a complete rotation of the output element with the aid of a high-resolution measurement system.

There is no change in the direction of rotation.

The transmission accuracy is defined as the sum of the absolute values of the maximum positive and negative deviation between the theoretical and the measured angular position of the output shaft.

Transmission accuracy

60.18 arcmin

P-012

x

P-012:The positioning resolution refers to the smallest angular change or positional change that can be distinguished by the positioning system.

With eccentric systems, the characteristic of the linearly resulting positioning resolution is described as a function of the angular position and thereby indicates the smallest positional change as a function of the angular position that can be distinguished by the positioning system.

With eccentric systems, it is defined such that at an angular position of 0 degrees, the eccentric is perpendicular to the resulting movement direction.

Resolution

0.0075 °

P-013

x

P-013:The torsional stiffness can be ascertained from the characteristic of the hysteresis curve of a gear.

The torsional stiffness is defined as the slope of the hysteresis line and describes the elastic torsional angle of the output shaft as a function of a torque.

The hysteresis curve is determined by subjecting the output to load while the input is blocked with a clockwise and an anticlockwise torque and the corresponding angular displacement measured.

Torsional stiffness

3.90 Nm/rad

P-014

x

P-014:The value for the lost motion can be ascertained from the characteristic of the hysteresis curve of a gear or linear actuator.

Lost motion is defined as the angular difference or position difference at which the two branches of the hysteresis curve cross the torque or force zero point, i.e., no load is applied.

The hysteresis curve is determined by subjecting the output to load while the input is blocked with a clockwise and an anticlockwise torque or a forward-acting and a backward-acting force and the corresponding angular displacement or positional change measured.

Lost motion

30 arcmin

P-015

x

P-015:The backlash can be determined from the course of the hysteresis curve of a gear or mechanical transmission system. The backlash is defined as the range in which the course of the hysteresis curve is vertical, i.e. there is a change in angle or position without changing the torque or force. The hysteresis curve is determined by loading the output with a clockwise and counterclockwise torque or force when the drive is blocked and measuring the associated angular torsion.

Backlash

20 arcmin

P-016

x

P-016:Rated torque or rated force is defined as the torque or force at which the service life is achieved under rated conditions, i.e., rated speed.

With drive systems, the motor torque may, in some cases, not be adequate for overcoming the running torque of the complete system under rated conditions.

Rated torque

T

10 mNm

P-017

x

P-017:The peak torque or peak force is the loading of the components in the drive train, e.g., the teeth of the gears, still below the fatigue strength.

This does, however, result in increased tooth wear, which leads to a reduction in the service life.

With drive systems, the motor torque may, in some cases, not be adequate for overcoming the running torque of the complete system at peak torque or peak force.

Peak torque

T

80 mNm

P-018

x

P-018:The momentary peak torque or momentary peak force describes the maximum permissible torque or force that can act on the actuator. If the momentary peak torque or momentary peak force is exceeded, damage or a reduced life time of the actuator cannot be ruled out. With momentary peak torque or momentary peak force, the elastic deformations of the teeth are still small enough that no tooth meshing problems occur and proper function is ensured. The loads do, however, exceed the limit of the fatigue strength. Thus, the number of loads should be minimised. Should it occur once, breakage or failure will not result. With drive systems, the motor torque may, in some cases, not be adequate for overcoming the running torque of the complete system at momentary peak torque or momentary peak force. In drive systems, the motor torque may not be sufficient to generate enough torque to meet the permissible momentary peak torque or momentary peak force. On the other hand, in drive systems, the existing motor torque can be so high that the drive system can exceed the permissible momentary peak torque or momentary peak force and the drive system can be damaged.

Momentary peak torque

T

100 mNm

P-021

x

P-021:Rated input speed is defined as the speed at which the service life is achieved under rated conditions, i.e., rated torque.

With drive systems, the motor torque may, in some cases, not be adequate for overcoming the running torque of the complete system at rated speed.

Rated input speed

n

10000 rpm

P-022

x

P-022:The maximum input speed refers to the speed before which mechanical damages occur to components in the drive train, e.g., scoring of the teeth or damage to the ball bearings.

With drive systems, the motor torque may, in some cases, not be adequate for overcoming the running torque of the complete system at maximum speed.

Maximum input speed

n

21000 rpm

P-023

x

P-023:Rated output speed or rated speed is defined as the speed at which the service life is achieved under rated conditions, i.e., rated torque or rated force.

With drive systems, the motor torque may, in some cases, not be adequate for overcoming the running torque of the complete system at rated speed.

Rated output speed

n

4.16667 rpm

P-024

x

P-024:The maximum output speed or maximum speed refers to the speed before which mechanical damages occur to components in the drive train, e.g., scoring of the teeth.

With drive systems, the motor torque may, in some cases, not be adequate for overcoming the running torque of the complete system at maximum speed.

Maximum output speed

n

8.75 rpm

P-026

x

P-026:The no-load starting torque describes the torque necessary for putting the gear into rotary motion without additional output-side load at 20°C and standard lubricant.

No-load starting torque

T

52.5 μNm

P-027

x

P-027:The running torque describes the torque necessary for driving the gear without additional output-side load at 20°C and standard lubricant at constant speed.

No-load running torque

T

35 μNm

P-028

x

P-028:The rated running torque describes the input-side torque that is required to operate the gear in rated operation, i.e., at rated torque and rated speed.

Rated running torque

T

685 μNm

P-055

x

P-055:The moment of inertia specifies a body’s resistance to change its rotational movement.

Moment of inertia

I

300 * 10-4 gcm2

P-063

x

P-063:

Kind of gear wheel input shaft

Worm

P-064

x

P-064:

Module gear wheel input shaft

0.25

P-065

x

P-065:

Number of teeth gear wheel input shaft

1

P-068

x

P-068:

Quality gear wheel input shaft

5

P-069

x

P-069:

Material gear wheel input shaft

1.4028 Fomblin GRM60

P-086

x

P-086:

Hardness mating gear wheel input shaft

worm gear

P-088

x

P-088:

Module mating gear wheel output shaft

0.25

P-089

x

P-089:

Number of teeth mating gear wheel output shaft

30

P-090

x

P-090:

Pitch diameter mating gear wheel output shaft

7.5

P-093

x

P-093:

Material mating gear wheel output shaft

CuBe2 (2.2147)

P-095

x

P-095:

Hardness mating gear wheel output shaft

hardened

Motor data: Stepper AM 0820-2R-A0.225

P-100

x

P-100:

Motortype

Stepper

P-102

x

P-102:The maximum speed of the motor describes the speed before mechanical damages occur to the commutator, the rotor or the bearing.

Maximum speed of motor

n

21000 rpm

P-103

x

P-103:Describes the step frequency at which the rotor can experience resonance vibrations while the motor is operated under no load. It is recommended that this frequency be avoided in normal operation and that the motor be started at a higher frequency or that half- or micro-steps be used. Additional inertial masses, e.g., through a gear, reduce the resonance frequency.

Resonance frequency of motor

f

170 Hz

P-105

x

P-105:Describes the torque developed by the motor while at a standstill.

Holding torque of motor (unpowered)

T

0.17 mNm

P-109

x

P-109:The phase current that may flow through both phase coils without the motor overheating while at an ambient temperature of 20°C and constant operation.

Rated current of motor

I

225 mA

P-111

x

P-111:The rated voltage corresponds to the voltage at which all other rated characteristic values of the motor, particularly the rated current at 20°C, are set, measured and classified.

Rated voltage of motor

U

2 V

P-112

x

P-112:The phase resistance describes the ohmic resistance of the coil of a phase at an ambient temperature of 20°C in the steady state.

Phase resistance of motor

R

7.3 ohm

P-113

x

P-113:Describes the inductance of the coil of a phase at an ambient temperature measured at 1 kHz.

Inductance of motor

L

1.4 mH

P-114

x

P-114:Describes the amplitude of the bemf.

Amplitude BEMF of motor

U

0.267 mV/rpm

P-115

x

P-115:The full step angle of the motor describes the angle at which the rotor turns if a phase is advanced.

Full step angle of motor

18 °

P-116

x

P-116:The angular accuracy of step describes the deviation of the current rotor position from the ideal target rotor position, whereby no external load is applied.

Angular accuracy of step of motor

±1.8 °

P-117

x

P-117:The electrical time constant describes the time required to achieve 67% of the possible phase current of a specified operating point.

Electrical time constant of motor

t

0.21 ms

P-118

x

P-118:The maximum temperature that may occur in the coil without destroying the magnets or the coil.

The coil temperature can be calculated by measuring the change in resistance and the temperature coefficient alpha, which is dependent on the coil wire material. T1 = 1/alpha * (R1/R0 + alpha*T0 – 1)

Max. coil temperature of motor

T

130 °C

P-119

x

P-119:Describes the thermal resistance of the motor between coil and housing.

Thermal resistance of motor between coil and housing

Rth1

4.1 K/W

P-120

x

P-120:Describes the thermal resistance of the motor between housing and ambient air.

Thermal resistance of motor between housing and air

Rth2

65.3 K/W

P-121

x

P-121:Describes the thermal time constant of the motor coil.

Thermal time constant of the coil of the motor

τw1

3500 ms

P-122

x

P-122:Describes the thermal time constant of the motor housing.

Thermal time constant of the housing of the motor

τw2

160000 ms

P-123

x

P-123:Describes the insulation voltage of the motor.

Insulation voltage of motor

U

200 V

Material information

P-901

x

P-901:

Lubrication of output bearing gearbox

Longtime PD2

P-903

x

P-903:

Lubrication of gear component set

Molykote BR 2 plus

P-904

x

P-904:

Lubrication of bearing motor

Synthetic light ester oil

P-908

x

P-908:

Material of gear component set

NiFe

P-909

x

P-909:

Material of output bearing gearbox

1.4108 DIN EN

P-911

x

P-911:

Material of bearing motor

Stainless steel

P-912

x

P-912:

Material of gearbox output side

1.4305 DIN EN

P-914

x

P-914:

Material of motor housing

Anodized aluminum

Axis 2: rotational axis

Nr.

Parameter

Symbol

Value

Material information

P-003

x

P-003:The reduction ratio describes the relationship between the input movement and the output movement. With a reduction ratio, the output movement is smaller than the input movement.

Ratio

i

500 : 1

P-008

x

P-008:The unidirectional repeatability describes the positional uncertainty that arises when repeatedly approaching a setpoint from the same direction with no load.

The repeatability is defined as half of the maximum difference together with a +/- sign.

Repeatability unidirectional

18.48 arcsec

P-009

x

P-009:The bidirectional repeatability describes the positional uncertainty that arises when repeatedly approaching a setpoint from the opposite direction with no load.

The repeatability is defined as half of the maximum difference together with a +/- sign.

Repeatability bidirectional

15.216 arcmin

P-010

x

P-010:The positioning accuracy of a gear describes the maximum deviation of the output angle relative to the setpoint or, with a linear actuator, the maximum deviation of the output position relative to the setpoint.

The measurement is performed during a complete rotation of the output element or a complete traverse of the travel range path with the aid of a high-resolution measurement system.

There is no change in the direction of rotation or direction reversal.

The positioning accuracy is defined as the absolute value of the maximum difference between the theoretical setpoint position and the measured actual position of the output element.

Accuracy

12.432 arcmin

P-011

x

P-011:The transmission accuracy of a gear describes the linearity error between input and output angle.

The measurement is performed during a complete rotation of the output element with the aid of a high-resolution measurement system.

There is no change in the direction of rotation.

The transmission accuracy is defined as the sum of the absolute values of the maximum positive and negative deviation between the theoretical and the measured angular position of the output shaft.

Transmission accuracy

24.864 arcmin

P-012

x

P-012:The positioning resolution refers to the smallest angular change or positional change that can be distinguished by the positioning system.

With eccentric systems, the characteristic of the linearly resulting positioning resolution is described as a function of the angular position and thereby indicates the smallest positional change as a function of the angular position that can be distinguished by the positioning system.

With eccentric systems, it is defined such that at an angular position of 0 degrees, the eccentric is perpendicular to the resulting movement direction.

Resolution

0.036 °

P-013

x

P-013:The torsional stiffness can be ascertained from the characteristic of the hysteresis curve of a gear.

The torsional stiffness is defined as the slope of the hysteresis line and describes the elastic torsional angle of the output shaft as a function of a torque.

The hysteresis curve is determined by subjecting the output to load while the input is blocked with a clockwise and an anticlockwise torque and the corresponding angular displacement measured.

Torsional stiffness

2.86 Nm/rad

P-014

x

P-014:The value for the lost motion can be ascertained from the characteristic of the hysteresis curve of a gear or linear actuator.

Lost motion is defined as the angular difference or position difference at which the two branches of the hysteresis curve cross the torque or force zero point, i.e., no load is applied.

The hysteresis curve is determined by subjecting the output to load while the input is blocked with a clockwise and an anticlockwise torque or a forward-acting and a backward-acting force and the corresponding angular displacement or positional change measured.

Lost motion

15 arcmin

P-015

x

P-015:The backlash can be determined from the course of the hysteresis curve of a gear or mechanical transmission system. The backlash is defined as the range in which the course of the hysteresis curve is vertical, i.e. there is a change in angle or position without changing the torque or force. The hysteresis curve is determined by loading the output with a clockwise and counterclockwise torque or force when the drive is blocked and measuring the associated angular torsion.

Backlash

0 arcmin

P-016

x

P-016:Rated torque or rated force is defined as the torque or force at which the service life is achieved under rated conditions, i.e., rated speed.

With drive systems, the motor torque may, in some cases, not be adequate for overcoming the running torque of the complete system under rated conditions.

Rated torque

T

10 mNm

P-017

x

P-017:The peak torque or peak force is the loading of the components in the drive train, e.g., the teeth of the gears, still below the fatigue strength.

This does, however, result in increased tooth wear, which leads to a reduction in the service life.

With drive systems, the motor torque may, in some cases, not be adequate for overcoming the running torque of the complete system at peak torque or peak force.

Peak torque

T

20 mNm

P-018

x

P-018:The momentary peak torque or momentary peak force describes the maximum permissible torque or force that can act on the actuator. If the momentary peak torque or momentary peak force is exceeded, damage or a reduced life time of the actuator cannot be ruled out. With momentary peak torque or momentary peak force, the elastic deformations of the teeth are still small enough that no tooth meshing problems occur and proper function is ensured. The loads do, however, exceed the limit of the fatigue strength. Thus, the number of loads should be minimised. Should it occur once, breakage or failure will not result. With drive systems, the motor torque may, in some cases, not be adequate for overcoming the running torque of the complete system at momentary peak torque or momentary peak force. In drive systems, the motor torque may not be sufficient to generate enough torque to meet the permissible momentary peak torque or momentary peak force. On the other hand, in drive systems, the existing motor torque can be so high that the drive system can exceed the permissible momentary peak torque or momentary peak force and the drive system can be damaged.

Momentary peak torque

T

46 mNm

P-021

x

P-021:Rated input speed is defined as the speed at which the service life is achieved under rated conditions, i.e., rated torque.

With drive systems, the motor torque may, in some cases, not be adequate for overcoming the running torque of the complete system at rated speed.

Rated input speed

n

10000 rpm

P-022

x

P-022:The maximum input speed refers to the speed before which mechanical damages occur to components in the drive train, e.g., scoring of the teeth or damage to the ball bearings.

With drive systems, the motor torque may, in some cases, not be adequate for overcoming the running torque of the complete system at maximum speed.

Maximum input speed

n

21000 rpm

P-023

x

P-023:Rated output speed or rated speed is defined as the speed at which the service life is achieved under rated conditions, i.e., rated torque or rated force.

With drive systems, the motor torque may, in some cases, not be adequate for overcoming the running torque of the complete system at rated speed.

Rated output speed

n

20 rpm

P-024

x

P-024:The maximum output speed or maximum speed refers to the speed before which mechanical damages occur to components in the drive train, e.g., scoring of the teeth.

With drive systems, the motor torque may, in some cases, not be adequate for overcoming the running torque of the complete system at maximum speed.

Maximum output speed

n

42 rpm

P-026

x

P-026:The no-load starting torque describes the torque necessary for putting the gear into rotary motion without additional output-side load at 20°C and standard lubricant.

No-load starting torque

T

52.5 μNm

P-027

x

P-027:The running torque describes the torque necessary for driving the gear without additional output-side load at 20°C and standard lubricant at constant speed.

No-load running torque

T

35 μNm

P-028

x

P-028:The rated running torque describes the input-side torque that is required to operate the gear in rated operation, i.e., at rated torque and rated speed.

Rated running torque

T

385 μNm

P-055

x

P-055:The moment of inertia specifies a body’s resistance to change its rotational movement.

Moment of inertia

I

283 * 10-4 gcm2

Motor data: Stepper AM 0820-2R-A0.225

P-100

x

P-100:

Motortype

Stepper

P-102

x

P-102:The maximum speed of the motor describes the speed before mechanical damages occur to the commutator, the rotor or the bearing.

Maximum speed of motor

n

21000 rpm

P-103

x

P-103:Describes the step frequency at which the rotor can experience resonance vibrations while the motor is operated under no load. It is recommended that this frequency be avoided in normal operation and that the motor be started at a higher frequency or that half- or micro-steps be used. Additional inertial masses, e.g., through a gear, reduce the resonance frequency.

Resonance frequency of motor

f

170 Hz

P-105

x

P-105:Describes the torque developed by the motor while at a standstill.

Holding torque of motor (unpowered)

T

0.17 mNm

P-109

x

P-109:The phase current that may flow through both phase coils without the motor overheating while at an ambient temperature of 20°C and constant operation.

Rated current of motor

I

225 mA

P-111

x

P-111:The rated voltage corresponds to the voltage at which all other rated characteristic values of the motor, particularly the rated current at 20°C, are set, measured and classified.

Rated voltage of motor

U

2 V

P-112

x

P-112:The phase resistance describes the ohmic resistance of the coil of a phase at an ambient temperature of 20°C in the steady state.

Phase resistance of motor

R

7.3 ohm

P-113

x

P-113:Describes the inductance of the coil of a phase at an ambient temperature measured at 1 kHz.

Inductance of motor

L

1.4 mH

P-114

x

P-114:Describes the amplitude of the bemf.

Amplitude BEMF of motor

U

0.267 mV/rpm

P-115

x

P-115:The full step angle of the motor describes the angle at which the rotor turns if a phase is advanced.

Full step angle of motor

18 °

P-116

x

P-116:The angular accuracy of step describes the deviation of the current rotor position from the ideal target rotor position, whereby no external load is applied.

Angular accuracy of step of motor

±1.8 °

P-117

x

P-117:The electrical time constant describes the time required to achieve 67% of the possible phase current of a specified operating point.

Electrical time constant of motor

t

0.21 ms

P-118

x

P-118:The maximum temperature that may occur in the coil without destroying the magnets or the coil.

The coil temperature can be calculated by measuring the change in resistance and the temperature coefficient alpha, which is dependent on the coil wire material. T1 = 1/alpha * (R1/R0 + alpha*T0 – 1)

Max. coil temperature of motor

T

130 °C

P-119

x

P-119:Describes the thermal resistance of the motor between coil and housing.

Thermal resistance of motor between coil and housing

Rth1

4.1 K/W

P-120

x

P-120:Describes the thermal resistance of the motor between housing and ambient air.

Thermal resistance of motor between housing and air

Rth2

65.3 K/W

P-121

x

P-121:Describes the thermal time constant of the motor coil.

Thermal time constant of the coil of the motor

τw1

3500 ms

P-122

x

P-122:Describes the thermal time constant of the motor housing.

Thermal time constant of the housing of the motor

τw2

160000 ms

P-123

x

P-123:Describes the insulation voltage of the motor.

Insulation voltage of motor

U

200 V

Material information

P-901

x

P-901:

Lubrication of output bearing gearbox

Longtime PD2

P-903

x

P-903:

Lubrication of gear component set

Molykote BR 2 plus

P-904

x

P-904:

Lubrication of bearing motor

Synthetic light ester oil

P-908

x

P-908:

Material of gear component set

NiFe

P-909

x

P-909:

Material of output bearing gearbox

1.4108 DIN EN

P-911

x

P-911:

Material of bearing motor

Stainless steel

P-912

x

P-912:

Material of gearbox output side

1.4305 DIN EN

P-914

x

P-914:

Material of motor housing

Anodized aluminum

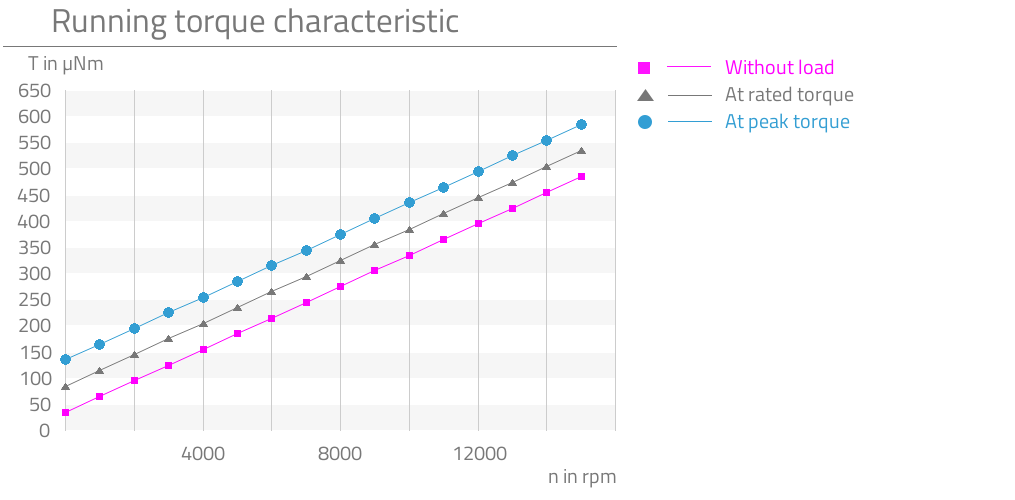

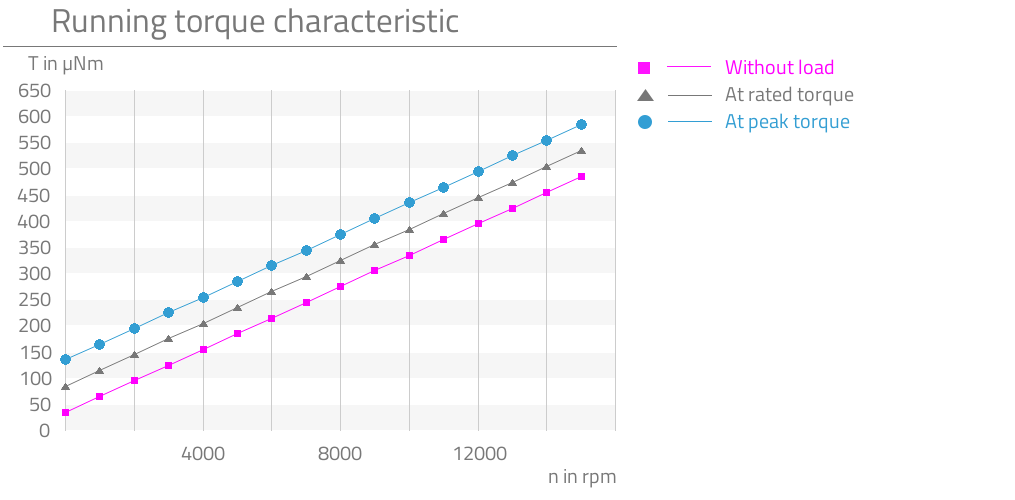

Graphs

P-019

P-029

P-019

P-029

Alternative products

Flexible integration

Easy controllability

Ball screw

Wide travel range

Transmission ratio optimized to torque

Vacuum suitable lubrication

Hollow shaft thru center of rotational axis

Use of high quality materials

Preloaded ball bearing

Transmission ratio optimized to speed

Preloaded ball bearing

Robust control without feedback system

Integrated tool fitting

Integrated vacuum supply for tool

High speed

High repeatability

Lifetime lubrication

Preloaded ball bearing

Zero backlash with optimised fit between speed and resolution

Integrated overload clutch to prevent for demaginig

Flexible integration

Vacuum suitable lubrication

Easy controllability

Ball screw

Zero backlash with speed optimised transmittion ratio

Compact build up

Dry lubrication due to coatings

Custom designed output shaft

Custom designed housing

Connecting cable assembled

Compact build up

Vacuum suitable lubrication

Robust control without feedback system

Integrated limit switches

Ball screw

High repeatability

Lifetime lubrication

Preloaded ball bearing

Easy controllability

Zero backlash with optimised fit between speed and resolution