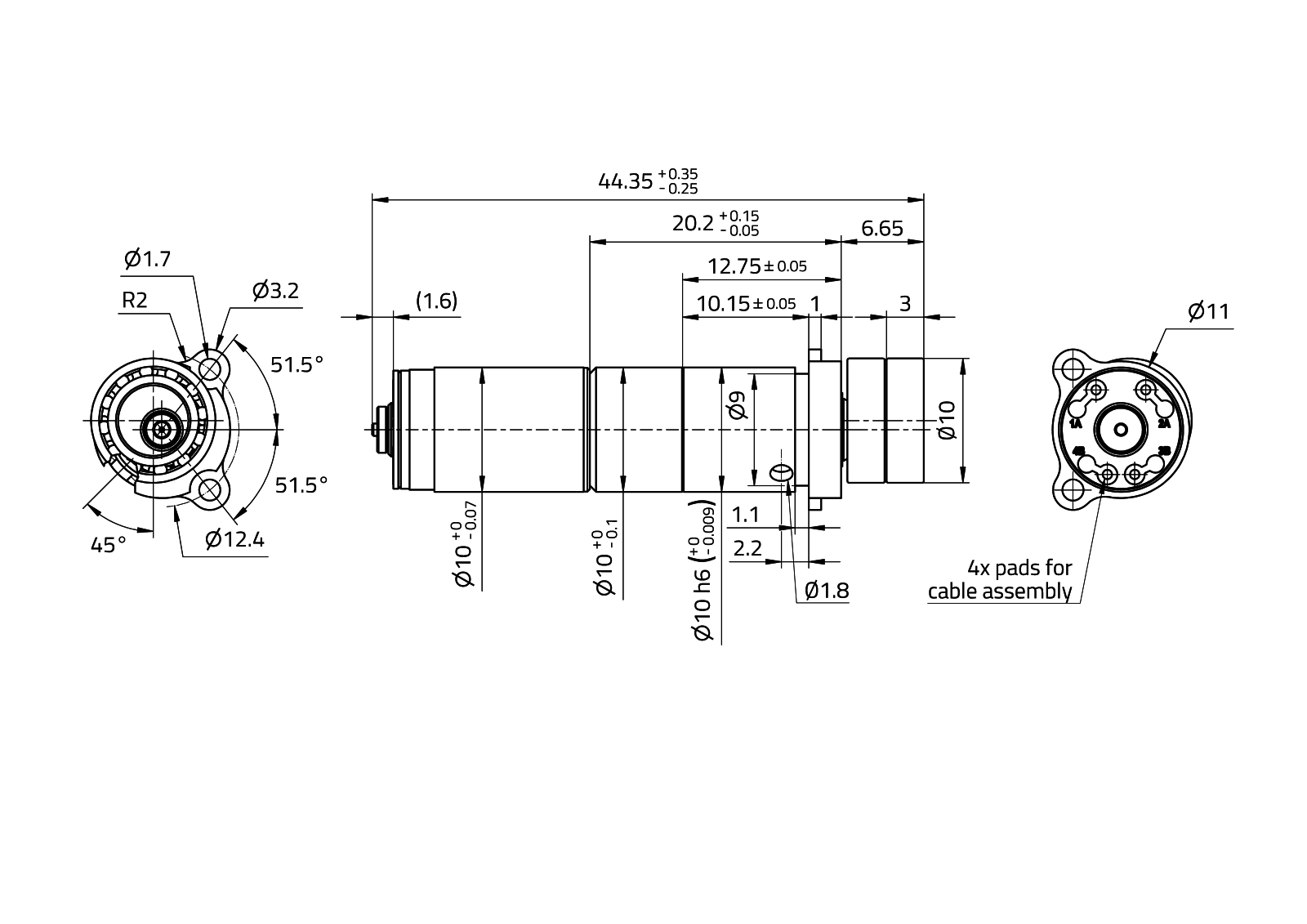

KeevoDrive® HighVac 10mm – Type 1

Thanks to the dry lubrication and the materials that are used, the KeevoDrive® HighVac 10mm – type 1 is especially well suited for applications in extreme environmental conditions.

The positioning unit, which is constructed for use in high-vacuum environments, is equipped with a stepper motor with 20 steps per rotation and thereby allows the system to be operated in a simple, open loop control.

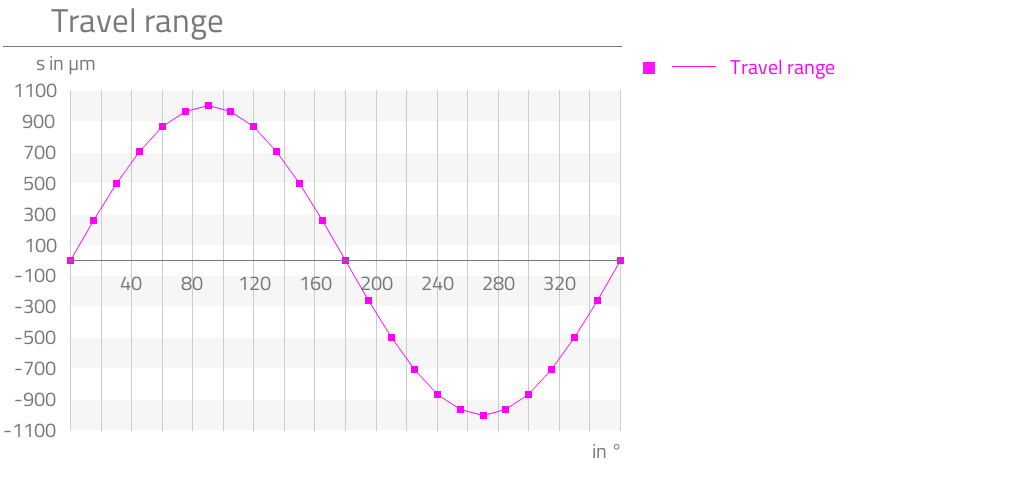

The micro positioning system is based on an eccentric with eccentricity of 1000 µm, thereby making possible a travel range of up to 2000 µm.

At the core of this exceptionally reliable micro system is a zero-backlash MaalonDrive® gear with a reduction ratio of 1000:1.

Benefits

1) Suitable in wide temperature range

2) Dry lubrication due to coatings

3) Robust control without feedback system

4) Zero backlash at ultra high resolution

5) Step with in the range of nm

Technical parameters

The values shown are based on calculations and measurement procedures carried out by Micromotion GmbH, which are carried out according to the current state of the art. Our definitions can be found at www.micromotion-drives.com. For further information please contact sales@micromotion.de.

Nr.

Parameter

Symbol

Value

Properties

P-001

Vacuum suitable

UHV

P-003

Ratio

i

1000 : 1

P-004

Self-locking

ja

P-005

Max. travel range

s

2000 μm

P-014

Lost motion

11.668 μm

P-015

Backlash

0 μm

P-016

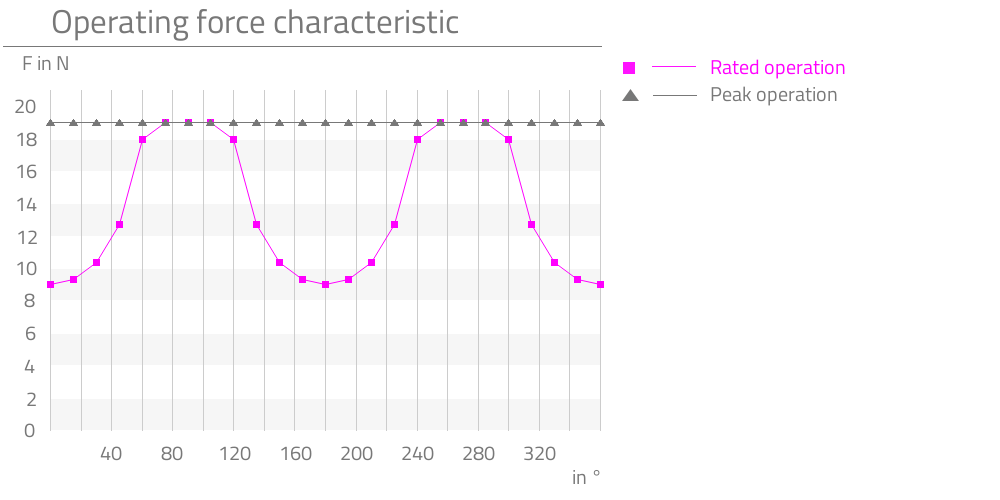

Rated force

F

9 N

P-017

Peak force

F

19 N

P-018

Momentary peak force

F

47 N

P-034

Lifetime for rated operation

200 h

P-035

Radial backlash output shaft

0 μm

P-036

Axial backlash output shaft

0 μm

P-037

Radial stiffness

c

69.13 N/μm

P-038

Axial stiffness

c

40 N/μm

P-039

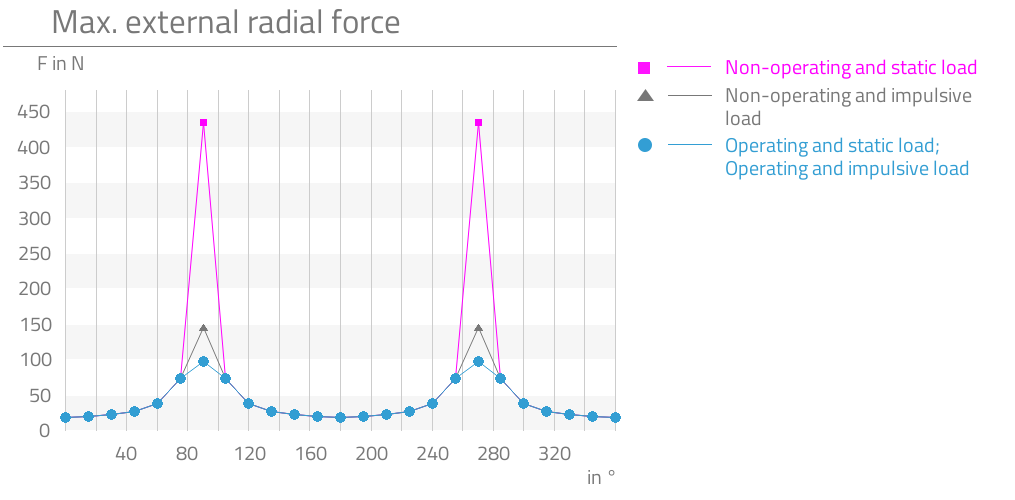

Max. radial load on output shaft (non-operating, constant load)

F

435 N

P-040

Max. radial load on output shaft (non-operating, impulsive load)

F

145 N

P-041

Max. radial load on output shaft (operating, constant load)

F

98 N

P-042

Max. radial load on output shaft (operating, impulsive load)

F

98 N

P-043

Max. axial load on output shaft (non-operating, constant

F

150 N

P-044

Max. axial load on output shaft (non-operating, impulsive load)

F

50 N

P-045

Max. axial load on output shaft (operating, constant load)

F

380 N

P-046

Max. axial load on output shaft (operating, impulsive load)

F

127 N

P-055

Moment of inertia

I

955 * 10-4 gcm2

P-056

Weight

m

19 g

P-057

Min. permissible ambient temperature (non-operating)

T

-63 °C

P-058

Min. permissible ambient temperature (operating)

T

-63 °C

P-059

Max. permissible ambient temperature (non-operating)

T

130 °C

P-060

Max. permissible ambient temperature (operating)

T

70 °C

Motor data: Stepper AM 1020-2R-A-0.25-8-01-A2017 dry lubrication

P-100

Motortype

Stepper

P-102

Maximum speed of motor

n

3000 rpm

P-103

Resonance frequency of motor

f

140 Hz

P-105

Holding torque of motor (unpowered)

T

0.2 mNm

P-109

Rated current of motor

I

250 mA

P-111

Rated voltage of motor

U

2 V

P-112

Phase resistance of motor

R

8 ohm

P-113

Inductance of motor

L

2.4 mH

P-114

Amplitude BEMF of motor

U

0.6 mV/rpm

P-115

Full step angle of motor

18 °

P-116

Angular accuracy of step of motor

±1.8 °

P-117

Electrical time constant of motor

t

0.32 ms

P-118

Max. coil temperature of motor

T

130 °C

P-119

Thermal resistance of motor between coil and housing

Rth1

3.9 K/W

P-120

Thermal resistance of motor between housing and air

Rth2

53.8 K/W

P-121

Thermal time constant of the coil of the motor

τw1

3200 ms

P-122

Thermal time constant of the housing of the motor

τw2

200000 ms

P-123

Insulation voltage of motor

U

200 V

Excenter data

P-501

Eccentricity

1000 μm

P-504

Max. radial load on eccentric bearing (non-operating, constant load)

F

19 N

P-505

Max. radial load on eccentric bearing (non-operating, impulsive load)

F

19 N

P-506

Max. radial load on eccentric bearing (operating, constant load)

F

19 N

P-507

Max. radial load on eccentric bearing (operating, impulsive load)

F

19 N

P-508

Max. axial load on eccentric bearing (non-operating, constant load)

F

150 N

P-509

Max. axial load on eccentric bearing (non-operating, impulsive load)

F

50 N

P-510

Max. axial load on eccentric bearing (operating, constant load)

F

380 N

P-511

Max. axial load on eccentric bearing (operating, impulsive load)

F

127 N

P-513

Eccentricity error

20 μm

Material information

P-900

RoHS compliant

ja

P-901

Lubrication of output bearing gearbox

MoS2(drylubrication)

P-902

Lubrication of input bearing gearbox

MoS2(drylubrication)

P-903

Lubrication of gear component set

DICRONITE®/MoS2(drylubrication)

P-904

Lubrication of bearing motor

MoS2(drylubrication)

P-907

Lubrication of eccentric bearing

MoS2(drylubrication)

P-908

Material of gear component set

NiFe

P-909

Material of output bearing gearbox

1.4108 DIN EN

P-910

Material of input bearing gearbox

1.4108 DIN EN

P-911

Material of bearing motor

Stainless steel

P-912

Material of gearbox output side

1.4305 DIN EN

P-914

Material of motor housing

Anodized aluminum

P-915

Material of eccentric bearing

1.4108 DIN EN

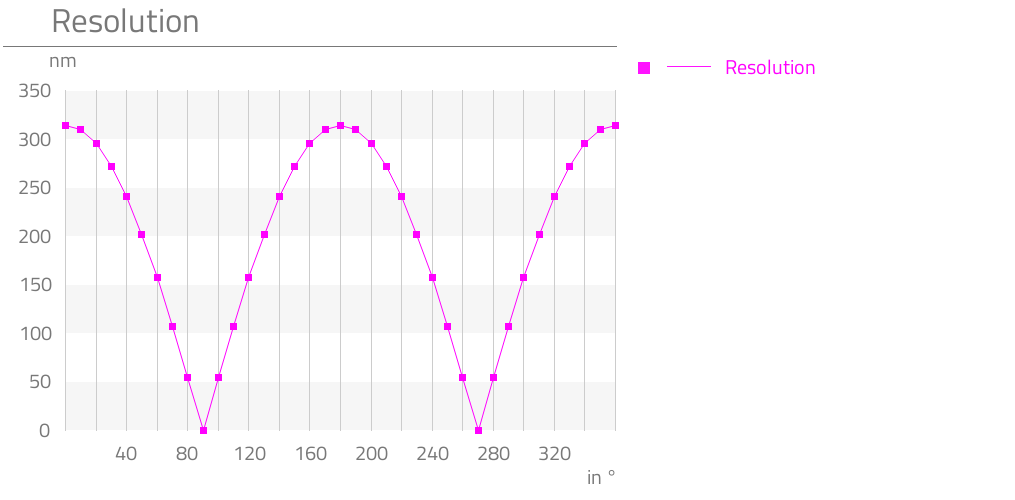

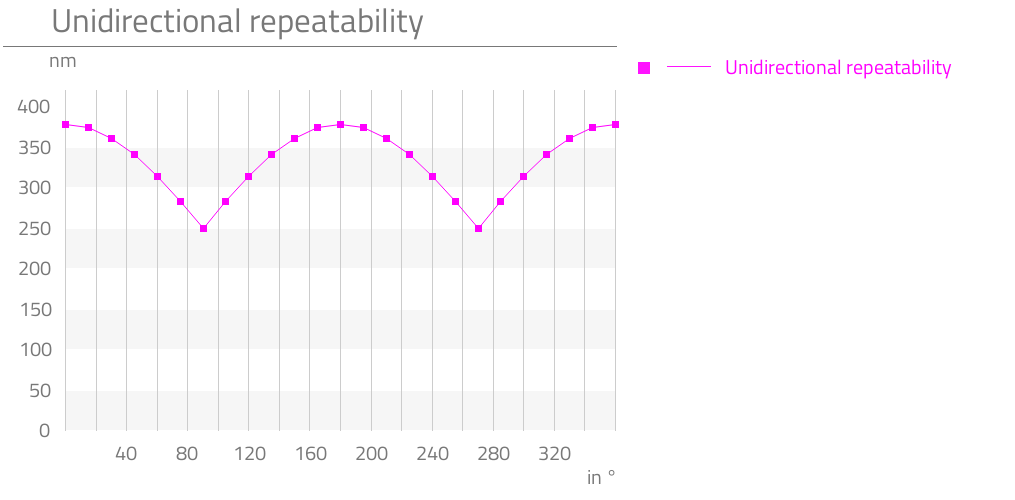

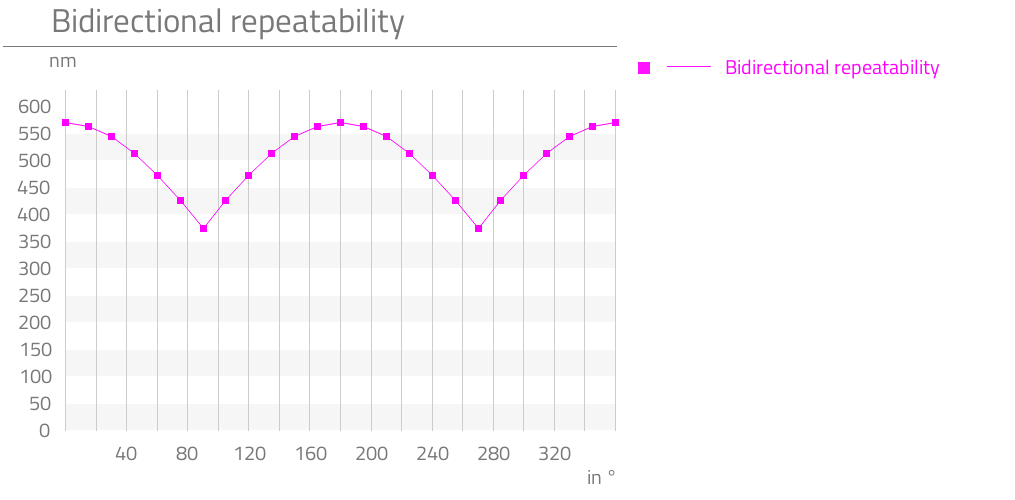

Graphs

P-512

P-502

P-016

P-012

P-008

P-009

P-005